DimensionCONTROL

OffLine profilometer TCP8302.T

Measurement system of width and thickness

More informationRetrofitPROGRAM

Retrofit of TG, TU, TUG and balancer machines

Excellent stability, cycle time and service

More informationSheet-of-lightPROFILOMETER

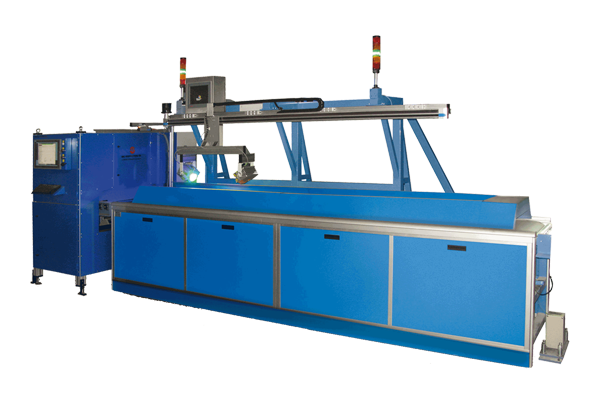

Integrated testing station

Thickenss, Width, Length and Weight measurement all in ONE

More informationMicro-Epsilon Inspection – specialists in inspection and measuring systems

Inspection and measuring systems form an inseparable part of the foundations for product safety and efficient manufacturing, while also reducing environmental harm from manufacturing processes. A well-set manufacturing tolerance, together with precise and stable inspection systems, saves you manufacturing costs, reduces your reject rate, and eliminates human error in the manufacturing process. Areas where Micro-Epsilon Inspection excels include measuring geometric factors at the micrometer level, measuring mass, measuring force effects, and checking materials’ surfaces, and all this with overall integration into the manufacturing process, primarily in the rubber and automotive industries.

A strong alliance

Micro-Epsilon Inspection is a member of the Micro-Epsilon group, an alliance of medium-sized companies that work with sensor technologies. The synergy of our respective areas of development and production, as well as our sharing of know-how, makes this group a strong alliance indeed.

Inspection systems for reflecting surfaces

Micro-Epsilon Inspection offers the world’s largest selection of highly precise inspection and measuring systems for the rubber industry.

Our customers at over 30 plants in 22 countries and on 4 continents rely on our high-quality products, timely deliveries, and highly valued fast and professional service—so see for yourself and try out our special offer for the delivery of your first device.

84101 Bratislava

Slovakia